Quality System

With professional experience, equipment, software, at any time for the needs of customers to provide services

Dao Siang have professional gauge and control software. The gauge strengthens the stability of quality in order to meet the standard. Control software uses MSA to manage and evaluate precision inspection equipment、use SPC to achieve professional auto-examine outcome in order to enhance inspect efficiency and provide correct figures. Dao Siang is extremely strict on every detail of manufacturing process. We can satisfy the needs of our customer by our professional experience、equipment、software.

Quality Policy

The primary principle:continuously improve quality、satisfy our customer and fully participate.

Our utmost principle is continuously improve quality、satisfy our customer and fully participate. Not only do we set up quality policy and quality standard operation procedure but we also implement precision inspection equipments in every process to fulfill our company principle.

Continuously Improve Quality

Putting efforts to improve technical skills、constantly improve quality and reduce costs so as to improve revenue and competitiveness

Satisfy Our Customer

Followed by our company philosophy, which are customer priority、quality enhancement、full participation and service innovation, and with wholeheartedly continuous improvement we have already reached 100% customer satisfaction.

Fully Participate

Widespread the awareness of quality to our employees and implement both labor division and integration of management responsibility, and strictly abide by the laws and customer's regulations.

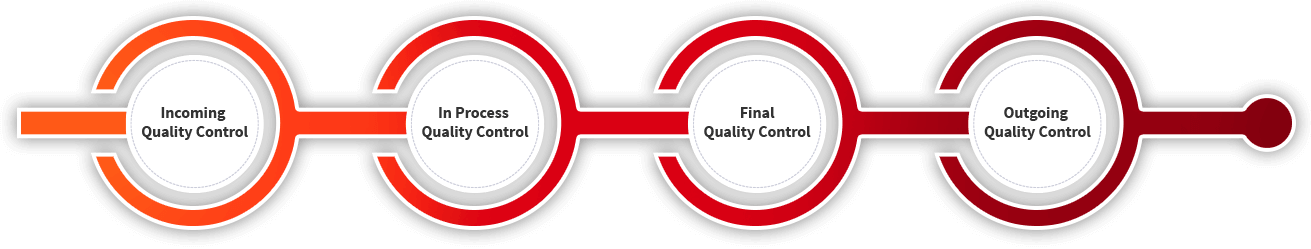

Quality Control Process

We have divided our stern quality control process into four procedures, which are IQC、IPQC、FQC、OQC. The Sampling rate and the number of examine times are decided by our customers based on their quality level of acceptance; moreover, ach product has different quality control standard to make sure the product meets the requirement. Our QA team not only has many years of experience but also trained to be a professional expert.

Quality control goal: We sell qualified products; we do not produce defective products.

IQC: In order to ensure the quality of materials in the pre-production quality requirements, all material needed to be in accordance with the standard inspection procedure、sampling plan、inspect items and acceptance level to undergo the inspection process and write down the record.

IPQC: During the manufacturing process from beginning to the end, we can perform first-article inspection、tour inspection、last-article inspection as long as it fits our customer’s needs.

FQC: All finished goods are inspected according to our quality standard for each project. Products are sampled according to the AQL sampling rate before it leaves our production plant into the warehouse.

OQC: Our QC team will randomly check any finished goods in the warehouse before it goes out for shipment. This last inspection ensures zero defect goods are shipped to our customer.

Inspection Equipment

Dao Siang imports high precision equipments from both domestic and abroad to enable our QC be more precise on verifying and, in the end, satisfy our customer. We believe that only through precision equipments and strict process control can build up high standard parts and, in the meanwhile, ensure the quality.

Quality Certification

ISO 9001:2015 Quality Management System

In order to assure the stability and consistency of the quality during processing, we get the ISO 9001: 2015 international standard quality assurance system award, which audited by AFNO in 2017, and the following year through third party certificated.

ROHS(The Restriction of Hazardous Substances in Electrical and Electronic Equipment)

Products from Dao Siang are RoHS compliant. RoHS regulations came into force on 1 July 2006 which bans the placing on the EU market of new electrical and electronic equipment containing more than agreed levels of lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyl (PBB) and polybrominated diphenyl ether (PBDE) flame retardants.Dao Siang will also provide reasonable documentation support for verification of part compliance with RoHS standards if necessary.